The Founder, Chairperson and CEO of Immersion4, a leader in immersive cooling, spoke to Teletimes International about the need for an eco-conservation & environmental approach and what his company is doing in that regard.

Khalid Athar: What is Immersion4?

Serge Conesa: Immersion4 is about cooling electronics with liquid. We immerse any kind of electronic components & PCB’s along with their connections in our ICETM Coolant liquid to keep them cool.

KA: Would you like to talk a little bit about the “AI for Good” event and why you chose that audience?

SC: In 2019, we were honored to receive the prestigious awards for the best use of ICT and the Global Excellence award by the ITU. It was a moment of great surprise for us as a fresh startup, emerging seemingly out of nowhere, to be recognized and invited by the ITU. What struck me the most was the realization that the ITU understood the intrinsic connection between data and energy. This realization was the validation of our work and prompted us to amplify this message further.

Today, the focus is on AI, which is fundamentally data driven. The consumption of data is skyrocketing, with exponential growth. In this context, I strongly believe that this audience is the ideal platform to encourage and inspire others to continue generating and utilizing data at an exceptional level but do that sustainably. It’s not only about excelling in AI on the software side, but also about adopting responsible practices in the production and storage of your data. This is precisely what Immersion4 embodies and promotes: leveraging the power of data for good, while ensuring sustainable and ethical data production processes.

KA: People must be asking you, “what’s immersive cooling got to do with AI”? How do you respond to that?

SC: Immersive Cooling is closely related to AI because it revolves around data generation produced by electronics. To ensure optimal performance, these electronics require efficient cooling methods, and this is where the challenge lies. Nowadays datacenters are traditionally air-based cooling and we all know that AIR is an insulator media with a very low thermal conductivity hindering effective heat dissipation. However, by employing liquid cooling a native thermal conductor for the entire computer system, we can harness the thermal conductivity of liquids, resulting in a remarkable 80% reduction in datacenter energy consumption and a drastic simplification of the cooling infrastructure allowing any building to become a datacenter.

Furthermore, current data centers contribute to environmental issues by emitting CO2, greenhouse gases, and micro particles. Immersive cooling addresses this concern by eliminating such pollution. Additionally, conventional electronic designs generate significant e-waste, mainly due to conventional coating and the use of brominated compounds on PCBs. However, using FULL immersion technology eliminates the generation of such waste entirely. Remember that the global generation of e-waste grew by 9.2 Mt since 2014 and is projected to grow to 74.7 Mt by 2030 almost doubling in only 16 years.

Moreover, our groundbreaking approach can already save 30 million lives, and it doesn’t stop there. We aim to establish manufacturing plants worldwide that fully embrace the principles of a circular economy, thereby creating employment opportunities and addressing significant challenges like cool migrations.

Lastly, it’s worth noting that while humans rely on air and water, electronics have no such dependency. In fact, our innovative liquid-based system ensures that electronics remain fully protected and functional without interfering with our vital resources. This way, everyone is content, as our liquid solution perfectly accommodates the needs of electronics while preserving what humans and biodiversity truly require.

KA: Would you like to talk a little bit about the problem of extreme energy consumption in the ICT space? How do you see the fact that the data we are storing may or may not be valuable but the energy used to store any data is extremely valuable – yet we continue down the same path?

SC: You are absolutely correct in saying that data may or may not have value but energy has one. I will add to your comment that “Data is Energy” and data should be considered “energy” as without energy there is no data. To be able to achieve and store the massive data production forecasted at around 175 Zettabytes in 2025, we must go back to the electronic fundamentals as a data center is all about cooling electronics. To be truly sustainable, electronic optimization must be the first thing that is addressed so any initiative such as algorithms optimization, virtual machine architecture implementation, and application software optimization without that prerequisite cannot be as an overall truly efficient.

We have entered an era where data can be considered as the 8th natural resource, and today data centers consume almost 1,5% of the world’s electricity. Data production implies heat generation. This is where all the Physics laws converge together defining the exchange rules. With the coming end of Moore’s law, new chips will need higher clock speeds to cope with performance demand. Even today’s 4nm bitcoin ASICS require a lot of power capacity and dissipate a tremendous amount of heat (500W+/cm2). The ability to remove high-density heat production, while reducing the electricity used to do this, is the key to performance for various chip industries.

It is obvious that we cannot continue down the same path.

In 2017, we saw exponential growth in data and a data center market explosion led by factories of the digital world (from EDGE to Hyperscale). Sadly, what we forecasted as worst-case scenarios are becoming reality with a direct impact on our quality of life. In 2016, studies revealed that datacenter represented % of the world’s electricity consumption, 3% of the GHG, and 926 billion liters of water in the US. In 2022, they represent worldwide 189Tws/hours or the equivalent on the electricity production of 189000 nuclear plant energy production at 1Gw/hours. FYI, today the world nuclear energy production represents 389 Gws/hours. They have also a direct impact on what we need the most, AIR and WATER. In average a datacenter consumes yearly 26 million liters of water and are accountable for 4% of the GHG emissions. As an example, Microsoft’s giant data center complex in North Holland consumed 84 million liters (84,000 cubic meters) of water in 2021, a year when heat caused severe water shortages. (Drought-stricken Holland discovers Microsoft data center slurped 84m liters of drinking water last year – DCD (datacenterdynamics.com). Other studies shows that the median water footprint at no less than 0.74 litres per GB of internet use so the water consumption impact is relevant and urgently needs to be considered.

KA: What is the key problem in our current approach towards data center cooling?

SC: Cooling electronics using an insulator (air) instead of a thermal conductor (liquid) does not make a lot of sense. Trying to reuse the heat dissipated by the IT load through air/liquid is also not efficient and requires huge investment. Often in my presentations, I’m asking if it makes sense to cool an entire room just to cool a glass of champagne. I can see most people smiling. Well, this is what today’s data center technology is about.

We are continuing on “ADDING” and “EXPANDING” this technology with more complicated infrastructure at every level instead of “SIMPLIFIYING” while delivering the same or higher DATA services with respect to Energy consumption and infrastructure.

It is imperative that we change the way we cool electronics which has a lot to do with the way we build data centers. Like any other technology, using the same principles, it just had complexity starting from the IT load supply chain vendors. Cheap liquid technologies, DLC, coldplates,.. don’t solve the data center infrastructure complexity and cost. We need solutions with impact in terms of Backup system and UPS reduction, pollution emission, reduction in density and floor space, preservation of natural resources, saving energy and reduction (elimination) of E-waste.

Electronics don’t need air or water to be cooled. In fact, this is where the problem resides, creating many direct and indirect implications such as data center urban integration and costly data center air cooled infrastructure which directly impact ROI and TCO.

The good news is that emerging technologies using immersive cooling are all going one step forward to FULL IMMERSIVE cooling systems.

As a systemic approach, it is key to take into consideration the whole “Heat chain” to:

•Reduce the temperature gradient from the CHIP across the PCB to limit the fatigue related issues thus reducing the life span and improving reliability,

•Increase recycle-ability,

•Effectively reduce energy consumption

Immersion cooling is now inevitable and the new way to cool chips past 500W using warm facility water (22C+) inlet temperatures.

KA: How does Immersion4 approach data center cooling?

SC: The Immersion4 mission is to cool electronics using our liquid called ICETM Coolant while using our open systems welcoming any type / any format / any brands. In term of efficiency, there is nothing better than collecting and recycling the digital heat through a “Liquid to Liquid”TM thermal design. Immersion4 DTMTM technology is based on 4 pillars and 4 principles that answer positively the COP26 requirement since 2018. I always have been convinced that the biggest source of energy we have on earth is what I called “Eco-conservation”. As a matter of fact, we have estimated that if all datacenter’s in the world today will be using Immersion4 technology we will just save globally 150 Tws/hours.. This represents the electricity produced by 15000 nuclear plants at 1Gw per year on a 10 years plan.

Today Immersion4 is 100% SDG, ESG and sharia laws compliant. Our Industrial business model called I4IBMTM (100% based on circular economy) shares the value chain enhancing community quality of life. Immersion4 DTMTM and IBCMinersTM systems allow 1 year ROI with up to 90% TCO. This is a true response to industry needs and ensures the migration to a sustainable data world where energy and infrastructure are used almost exclusively to power the IT load instead of a cooling system.

I would like to add that Immersion4 DTMTM systems don’t emit any GHG or C02 nor consume any water.

In today’s world, we must build an eco-conservation society and the recycling of what we are producing is mandatory. The planet doesn’t buffer our lifestyle anymore. It is now becoming a question of survival.

KA: How is Immersion4 different from other immersion cooling solutions?

SC: There are many differences from the company structure to its product Series and architectures.

•Immersion4 mission and addressable markets – Immersion4 mission is two-fold. First to address all market segments from SME’s to fortune 500 including civilian and government. Through circular economy, to help any nations which is having a true sustainable agenda. In that regards we have created our own recyclable product lines and biodegradable liquids. Our go to market called I4IBMTM “Immersion4 Industrial Business model” creates partnership with countries allowing our systems to be produced locally as well as creating R&D Labs in partnership with local universities.

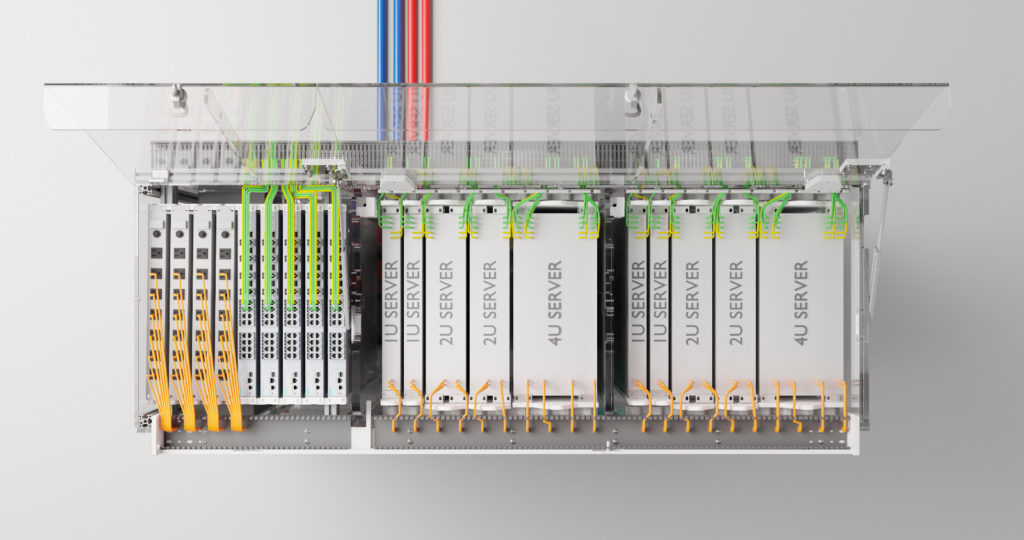

•Product ranges – Immersion4 has 2 Series of products called AIO “All In One” and DC “Datacenter”. They all use the same architectures outside of the fact that one has an integrated cooling module and the other does not. Otherwise, everything is common allowing the Immersion4 customer to operate any of our products as soon as he engages with one.

•Business model – It is “Pay as you Grow” based. DTMTM and IBCMinersTM systems can be added in any datacenter without any bottleneck expanding with the customer needs.

•IT Load simplification – The picture below is self-explanatory. Immersion4 “FULL IMMERSION” is a clear choice and our DTMTM systems should have no servicing issues. They have been engineered to easy any integration in any environment with a real-time IT Load thermal management while allowing servicing and commissioning “like an AIR cool rack”.

KA: What will be your key focus for the remainder of this year and what do you expect from the industry in the next 18 months?

SC: This is a very exciting time as during the 2023 “AI for good” summit organized by the ITU in Geneva, we are launched Immersion4 worldwide. We are also starting active deployment in UAE and in the Middle East in general with well-known customers. We are hoping the industry will soon realize how we help avoid complexity and cost just by being back to the fundamentals. Immersion4 Open Architecture integrates any type of IT load and will become a true problem solver for the all types of stakeholders. The future outlook is very promising and we remain motivated to play our role in making the world a better place.

A regulatory framework will be required to support more sustainable and responsible stages of open and closed reverse supply chains in the electronics sector but it’s NOT what will make the change. The change will come from the consciousness of each of us and our awareness of what we leave behind for future generations.